How to finish your lines..

Make sure everything is clean before soldering.

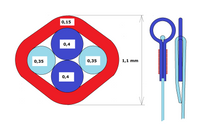

A piece of steel wire with a diameter of 0.4 mm and a length of 5 cm is needed for each end.

After cleaning, it must be tin-plated first.

Also the end of the line that is already bent, as shown to make 15.92 m, must be tinned first.

Stainless steel requires special flux (let us know if you need help to get the right flux)

The bending of the eye must be very precise because the 2 "legs" must be without any gap.

Finally, line and eye are joined and wrapped with 0.15 mm . thin bare copper wire

You can now solder with very little flux.

Caution : Too much flux can be harmful due to the corrosive effect.

If everywhere where flux goes, tin-plating also takes place, it is good.

Click to enlarge